- Core Technical Features

- Exceptional Short-Circuit Withstand Capability: To mitigate the risks associated with grid short-circuit faults, the winding employs a "multi-layer tight winding combined with resin-impregnated solidification" process. High-strength insulating spacers are inserted between winding layers to form a rigid, monolithic structure that enhances mechanical integrity under electromagnetic stress. Elastic fastening elements are installed at the interfaces between the core assembly and the tank, effectively absorbing transient electromagnetic forces during short-circuit events. Test results confirm a 15% improvement in short-circuit resistance and a 60% increase in post-fault recovery rate, significantly reducing the likelihood of power grid outages.

- Superior Short-Time Overload Capacity: Through innovative optimization of the cooling architecture, the winding integrates a hybrid configuration of radial oil ducts and axial heat dissipation channels, increasing the effective surface area for thermal dissipation by 35%. Furthermore, high-thermal-conductivity insulating paper is utilized to enhance internal heat conduction efficiency. These thermal design improvements enable the transformer to sustain operation at 1.3 times the rated load for up to 4 hours and at 1.5 times the rated load for 1 hour, while maintaining hotspot temperature rises within the allowable limits of the insulation system. This capability is especially beneficial in addressing fluctuating demand during peak load periods in urban and rural power distribution networks.

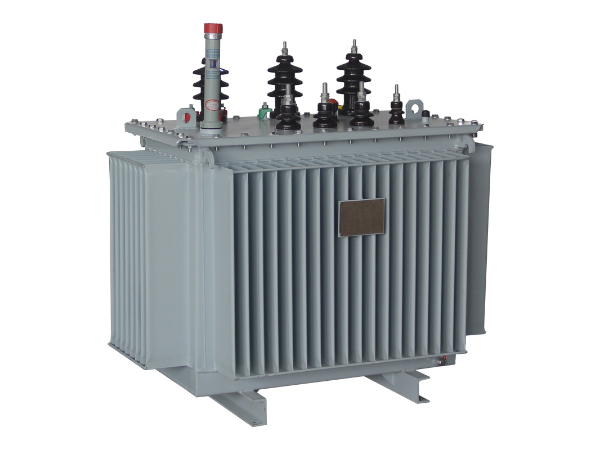

- Distinctive Structural Design

- High-Strength Single-Sheet Formed Tank: The tank is manufactured from a single steel plate using an integrated pressing and bending process, eliminating conventional multi-panel welding. This approach reduces the number of weld seams by 90% and increases overall compressive strength by 50%. The inner surface undergoes phosphating treatment followed by application of a corrosion-resistant coating, improving anti-corrosion performance and extending service life beyond 10 years.

- UV-Resistant Cover Flange Structure: The tank cover incorporates a 90° downward-inclined flange along its periphery, functioning as an integral sunshield that blocks over 80% of direct ultraviolet radiation from reaching the top sealing gasket. The gasket, made of weather-resistant EPDM rubber, benefits from both material durability and physical shielding provided by the flange, resulting in a 70% reduction in aging rate. This dual-protection mechanism effectively prevents oil leakage due to seal degradation and reduces long-term operational maintenance requirements.